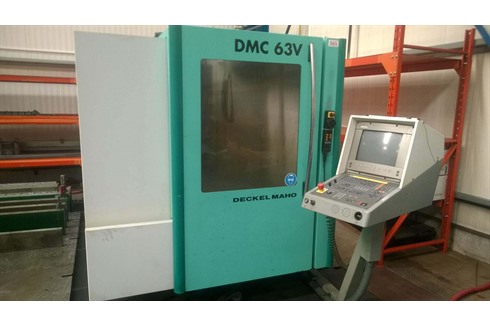

The used Deckel Maho DMC63V, was manufactured by Deckel Maho, a company adquired by Gildemeister in 1994 that changed its name to DMG. When searching used Deckel Maho DMC 63 v, it is useful to verify that the directions manual and working guidelines, the information sheet spec are additionally accessible, best as PDF. Purchasing utilized Deckel. Spindle speed: 8000 Rpm - Spindle power: 10 CV - Strokes X x Y x Z: 630 x 500 x 500 mm - Cone ISO 30CM - Running hours: 29800 - Hours under power: 65000. Dmc 63v Fast vertical milling / drilling center with integrated tool changer with fixed 24 positions, rpm 10,000, chip conveyor etc.Immediate availability!!!! Supplier and product research. Targeted search for over 3,800 companies; Search among 500,000 products; Social Media Ranking. Social media usage statistics.

When defining our capabilities, we mean more than the physical limits of our machinery, but rather every asset we have and use to maintain our Mission Statement. The People, Equipment, and Processes - all working as one to ensure you have the best product, for the best value, and it performs at the highest possible level in your manufacturing process.

Dmg 635

10 engineers with skills in CAD/CAM/CAE. Rapid prototyping and CAD/CAM software are some of the tools we use for R&D and Engineering products to fit the customer's varying needs. With systematic implementation of ISO procedures during Verification & Validation of all new product developments. ISO 9001:2008 Certification of all manufacturing processes. Average years of experience and knowledge in our engineering staff is 15 years.

State-of-the-art manufacturing equipment with full PM maintenance program to maintain accuracy and functionality of the equipment to its fullest extent. 5-Axis equipment including Mazak Integrex 200 IV ST machines, 5-axis Mazak Vari-Axis machines, 4-axis DMG 63V Machining centers, Haas VF-2 milling centers, and Studer CNC Universal Grinders. Quality Control equipment includes CMM equipment, complete in-process gauging systems integrated with Quality work-check sheets for product/process traceability and complete ERP system to reduce/eliminate repeat quality issues. All products precisely balanced on state-of-the art balancing equipment.

Dmg 635v

Processes

Dmg 64v

All of our manufacturing employees have been trained and continually updated on advance ISO standards and ERP system usage. Quality check worksheets maintained for traceability to lot numbers. Rejection rate is less than 0.05% of Turnover. All in-process orders are auto-generated for on-line production tracking of process flow. All employees participate in a systematic implementation of ISO procedures during Verification & Validation of new product developments.